It is a ore washing equipment for mechanical classification by means of different settling speeds of solid particles of different specific gravity in liquid. 【Processing capacity】: 35-50t/h 【Scope of application】: Xinhai Mining Spiral Trough Scrubber has good washing effect for ore with a certain proportion of mud content, and has been widely used in phosphate rock, iron ore and other ore washing and desliming operations; Fragmentation is particularly effective, suitable for processing hard-to-wash ores that contain less bulk ores and more mud, and are not suitable for processing brittle materials.

The spiral groove washing machine has the characteristics of simple structure, easy installation, low power consumption, easy operation, low manufacturing cost and good desliming effect. Under the agitation of the double-row blades on the screw shaft of the washing machine, the ore slime cemented into agglomerates can be separated, and the desliming effect is remarkable.

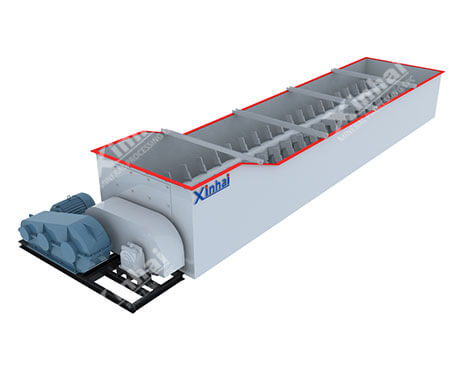

The double spiral chute washer is composed of a tank body, the left and right spiral blade shaft and transmission device. The motor drives the two spiral shafts to produce the relative rotation through the reducer, big and small gears. The blades on the spiral shafts are stagger installation. The material is fed from the lower part of the tank body into the middle of two spiral shafts. The mud mass and the ore particles adhering to the surface of the mud are washed by the high-pressure water fed from the upper part of the tank body according to the blade rubbing and scrubbing, so that the ore mud can be broken and the ore particles are separated. The washed fine mud is discharged by the overflow outlet that is installed at the back of the tank body, and the scrubbed ore is transported to the ore outlet at the front of the tank through the rotating spiral blade shaft, and then discharge.

| Model | Lengthe of body(mm) | Width of body(mm) | Production capacity(t/h) | Feed size(mm) | Inclination | Pitch(mm) | Motor | Weight(kg) | |

| Model | Power(kW) | ||||||||

| CXK1566 | 6660 | 1500 | 35-40 | <75 | 10.84° | 300 | Y200L2-6 | 22 | 15800 |

| CXK1676 | 7630 | 1600 | 40-50 | 10° | Y250M-6 | 37 | 17168 | ||

In a certain iron and phosphorus polymetallic ore beneficiation project, the surface of the ore contains a lot of slime, which interferes with the separation and purification of apatite, magnetite and other minerals. Therefore, Xinhai uses a spiral groove scrubber to wash the minerals. The ore desliming operation has a remarkable desliming effect, effectively ensuring the separation and purification of minerals.