A medium and fine crusher equipment, the spring is not only a safety device but also affects the crushing force. 【Processing capacity】: 12~1000t/h 【Scope of application】: The cone crusher mainly crushes ores and rocks with medium or above hardness, such as iron ore, copper ore, limestone, granite, quartz, etc. The form of the crushing cavity is determined by the use of the ore: the standard type is suitable for medium crushing; the medium type is suitable for medium and fine crushing; the short-head cone crusher is suitable for fine crushing.

The moving cone rotates continuously, the crushing process and the discharging process of the material are alternately and continuously carried out along the working surface, and the productivity is high;

The material is sandwiched between the two cones and subjected to extrusion, bending and shearing, so it is easier to break and the power consumption is low;

The product material is more uniform, in the shape of a cube, and the wear of the working surface of the moving cone is also more uniform;

Structure introduction, the structure of cone crusher mainly includes frame, horizontal shaft, moving cone, balance wheel, eccentric sleeve, upper crushing wall (fixed cone), lower crushing wall (moving cone), hydraulic coupling, lubrication system, Hydraulic system, control system and other parts;

Both the moving cone and the fixed cone are upright. When the moving cone swings, there is a parallel belt with an equal gap between the moving cone and the fixed cone near the discharge port of the crushing chamber, so that the finished product is uniform. The size of the feeding port is not large, and all materials that can be processed are primary crushed materials;

This series of cone crushers adopts two sealing methods of dry oil or water, so that dust and impurities cannot enter the body, so as to ensure the cleanliness of lubricating oil, prolong the service life of sliding bearings and thrust ball bearings, and make the machine run reliably.

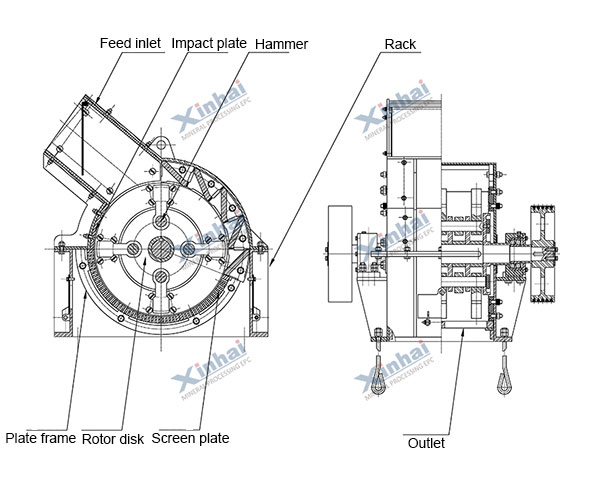

The working principle of hammer crusher mainly relies on impact energy to complete the crushing operation. When working, the motor drives the rotor to rotate at a high speed, and feeds the material into the crusher cavity evenly, and rotates the hammer head at high speed to impact, shear, and tear the minerals to break the ore. The rotating hammer head rushes to the baffle plate and sieve bar in the frame, leaving the material larger than the sieve hole on the sieve plate to continue to be hit and ground by the hammer head, and the sieved material is discharged directly.

| Type | Model | Diameter of Crushing Cone (mm) | Inlet Dimension (mm) | Max. Feed Size (mm) | Adjustment Range of Outlet (mm) | Motor Power (kW) | Capacity (t/h) |

| Standard | PYB-600/75 | 600 | 75 | 65 | 12 ~25 | 30 | 40 |

| PYB-900/135 | 900 | 135 | 110 | 15 ~50 | 55 | 50 ~90 | |

| PYB-1200/170 | 1200 | 170 | 145 | 20 ~50 | 110 | 110~168 | |

| PYB-1750/250 | 1750 | 250 | 215 | 25 ~60 | 155 | 280~480 | |

| PYB-2100/350 | 2100 | 350 | 300 | 30 ~60 | 280/210 | 500~800 | |

| PYB-2200/350 | 2200 | 350 | 280 | 500~1000 | |||

| Middle-sized | PYZ-900/70 | 900 | 70 | 60 | 8~20 | 55 | 20 ~65 |

| PYZ-1200/115 | 1200 | 115 | 100 | 8~25 | 110 | 42~135 | |

| PYZ-1750/215 | 1750 | 215 | 180 | 10 ~30 | 155 | 175~320 | |

| PYZ-2200/275 | 2200 | 275 | 230 | 280 | 200~580 | ||

| Short Head | PYD-600/40 | 600 | 40 | 35 | 3~13 | 30 | 12 ~23 |

| PYD-900/50 | 900 | 50 | 40 | 55 | 15 ~50 | ||

| PYD-1200/60 | 1200 | 60 | 50 | 3~15 | 110 | 18 ~105 | |

| PYD-1750/100 | 1750 | 100 | 85 | 5~15 | 155 | 75~230 | |

| PYD-2200/130 | 2200 | 130 | 100 | 280 | 125~350 |

The working principle of the spring cone crusher is driven by a motor, and the linkage of gears makes the driveshaft and transmission gear drive the eccentric sleeve to rotate. The moving cone of the spring cone crusher makes a rotary motion under the action of the eccentric sleeve. The moving cone and fixed cone close or dissociate with each other, thus continuously impacting and crushing the material.

The structure of spring cone crusher is mainly composed of frame, fixed cone, moving cone assembly, spring mechanism, bowl shaft frame and transmission.