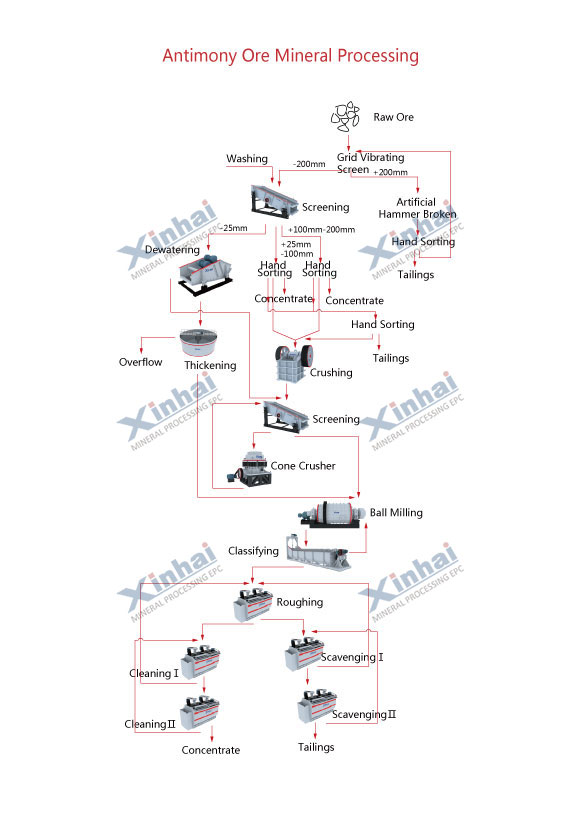

Proportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation. This method has many features, high efficiency, energy saving, and environment protection, which can make the low-grade ore enrichment advance. After gravity separation, the antimony will be purified by floatation. So the processing method of Xinhai is gravity separation-flotation process.

The ore after hand sorting will go through coarse crushing and fine crushing, during which the size of mineral should be under 30mm, and screening classification have three size fractions, 8-30mm, 2-8mm, 0-2mm.

Then the three kind of minerals will go respectively into Xinhai AM30 Jig, Xinhai LTA1010/2 Jig, and Xinhai Sawtooth Wave Jig to gravity separation. The mixted concentrate from the last stage will be go into the gravity concentrate district.

Then after the process of gravity, there will be a process of flotation, the tailings from the preview gravity separation will be grinded, separated, stirred, and separated. And the flotation will apply the process of one roughing, three cleanings, and two scavenging. Then high grade antimony fine powder will be produced. The tailings from the flotation will be reelected by shaking table to recycle the fine antimony particles, which we can get high grade antimony concentrate and tailings.

For massive bonanza in coarse particle size, Xinhai adds handsorting in crushing flow. The massive bonanza are sorted and the tailings enter gravity separation.

The content of antimony in antimony ore in a Xinhai project is 3.19%. Among them, antimony sulfide accounts for about 95.30% of the total antimony, and a small amount of antimony occurs in the oxide antimony or antimonate, accounting for about 4.70% of the total antimony; the carbon content in the ore is 6.43%, of which the inorganic carbon is as high as 5.46% , belongs to the high-carbon refractory antimony sulfide stone. After the multi-plan experiment of Xinhai Research Institute, it was determined that the combined process of gravity separation and flotation should be used to recover antimony ore. The mixed antimony concentrate with antimony grade of 58.71% and recovery rate of 93.75% was finally obtained. Xinhai realized the large-scale recovery of antimony ore. The recovery of strength reduces the pollution of tailings to the environment and brings huge economic benefits.

流程图

流程图