Chrome ore deposits are mined by both underground and surface techniques. Most chrome ore must be processed by the chrome ore processing plants. the mainly chrome ore beneficiation method is gravity separation. So the mainly used chrome ore concentrating equipments are ore washbox (sometimes it is called jigger), concentrating table, spiral classifiers, etc.

For chrome processing technology, there are gravity separation, flotation, magnetic separation and other methods. Xinhai will determine the final processing technology according to the ore characteristic analysis report and mineral processing experiment report.

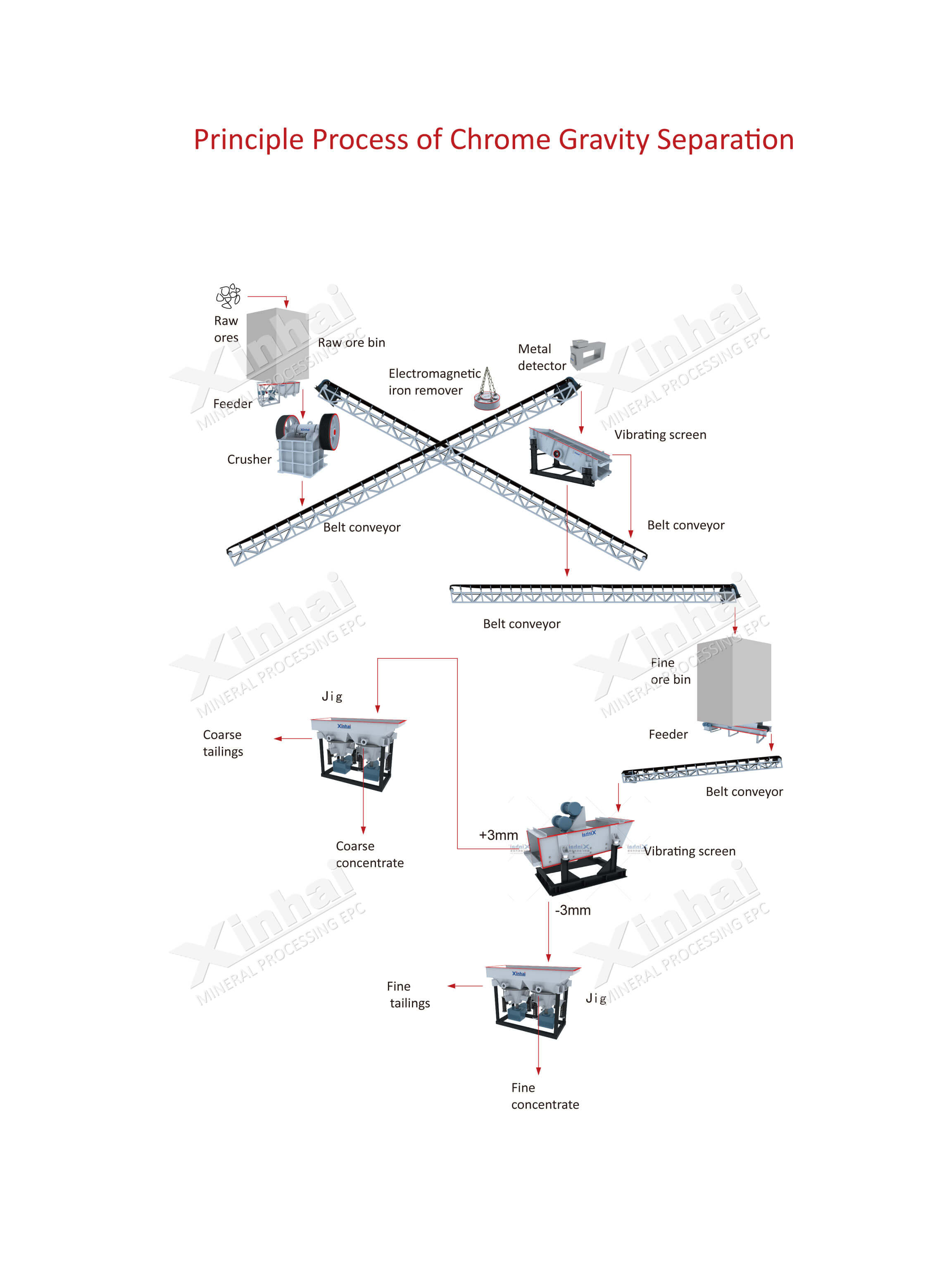

The common gravity separation flows is that: through crushing and grinding, the reasonable fineness of chrome ores are cleaned and classified by the spiral classifier with the help of the different specific gravity of the solid particles and the different precipitation speeds in the liquid.

Then use a jig machine and a shaker to wash the materials and transport them to the spiral chute to sort fine-grained mineral powder.

After screening, the slurry is sent to flotation cell or magnetic separator. The concentrates are dewatered after flotation.

After dewatering, the concentrates can be sent to the dryer. The dry concentrates can be directly used or re-grinding to pick up minerals.

Xinhai adopts gravity separation process for a chromite ore dressing plant. The chrome grade is over 30%, which is a rich ore, and there are lean chrome ore of different grades near the ore. Selected research, the final mining area has a strong magnetic separation tail throwing-shaking table full-grain classification and separation process. Under the grinding particle size of -200 mesh 60%, the final grade of concentrated chromium ore is 39.9%, and the recovery rate of chromium reaches 39.9%. 64.56%.

流程图

流程图