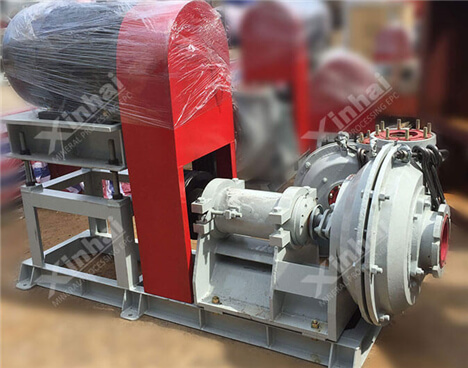

A wear-resistant slurry pump suitable for conveying slurry concentration within 65%. 【Processing capacity】: Flow≤1500m³/h 【Scope of application】: Xinhai wear-resistant slurry pump is suitable for handling abrasive slurry or corrosive fluid containing solid materials, exceeding that of metal and other types of pumps.

Xinhai wear-resistant slurry pump has a long service life and unique production technology, so that the content of natural rubber is about 97%, and the wear-resistant index is high, which is more than 2-4 times longer than other wear-resistant materials;

High efficiency and low energy consumption, the proportion of rubber material in the inner lining is small, the lining is light, the speed of the impeller is increased, the flow rate is 10-20% higher than that of ordinary rubber pumps, and the efficiency is increased by more than 30%;

Low noise, less maintenance, and smaller rubber-lined impeller, which reduces noise pollution, reduces maintenance of a large number of personnel, and reduces operating costs;

The flow parts are smooth and stable, and the fluid runs more smoothly.

The working principle of the wear-resistant slurry pump is to use the motor to drive the impeller to rotate to force the fluid to rotate, so that the impeller does work on the fluid along its moving direction, forcing the pressure potential and kinetic energy of the fluid to increase. Under the action of the inertial force of the fluid, The center flows to the edge of the impeller, and flows out of the impeller at a high speed, enters the press-out chamber, and is discharged through the outlet pipe.

The main components of wear-resistant slurry pump includes impeller, motor, sheath etc.

| Model & Spec. | Flow (m3/h) | Max. Head (m) | Rotating Speed (r/min) | Max. Rated Power (kW) | Max. Efficiency (%) | Impeller Diameter (mm) | Weight (kg) | Overall Dimension (mm) |

| XPA 50/50 | 20 ~60 | 38 | 800~2400 | 22 | 51 | 200 | 156 | 725X482X491 |

| XPA 80/80 | 30~100 | 45 | 600~2100 | 45 | 53 | 256 | 326 | 915X590X595 |

| XPA 100/100 | 60~160 | 50 | 600~1600 | 75 | 57 | 340 | 440 | 999 X 648 X 660 |

| XPA 150/125 | 100~260 | 47 | 400~1400 | 110 | 63 | 372 | 608 | 1280X736X758 |

| XPA 200/150 | 160~450 | 47 | 450~1200 | 132 | 69 | 433 | 736 | 1313X788X822 |

| XPA 250/200 | 300~900 | 46 | 400~1200 | 250 | 78 | 454 | 1250 | 1600X812X956 |

| XPA 300/250 | 400~1500 | 45 | 300~900 | 600 | 73 | 610 | 1956 | 1698X966X1083 |

A gold ore dressing plant in Shandong has a very high slurry temperature after separation. After using a common slurry pump, the equipment damage rate is very high, and the dressing cost is embarrassing. Contact Xinhai Mining through the Internet search platform, and the technicians recommend the use of XPA wear-resistant rubber slurry pump. The equipment not only inherits the advantages of the original slurry pump, but also has a good elasticity to buffer the impact force of the slurry.