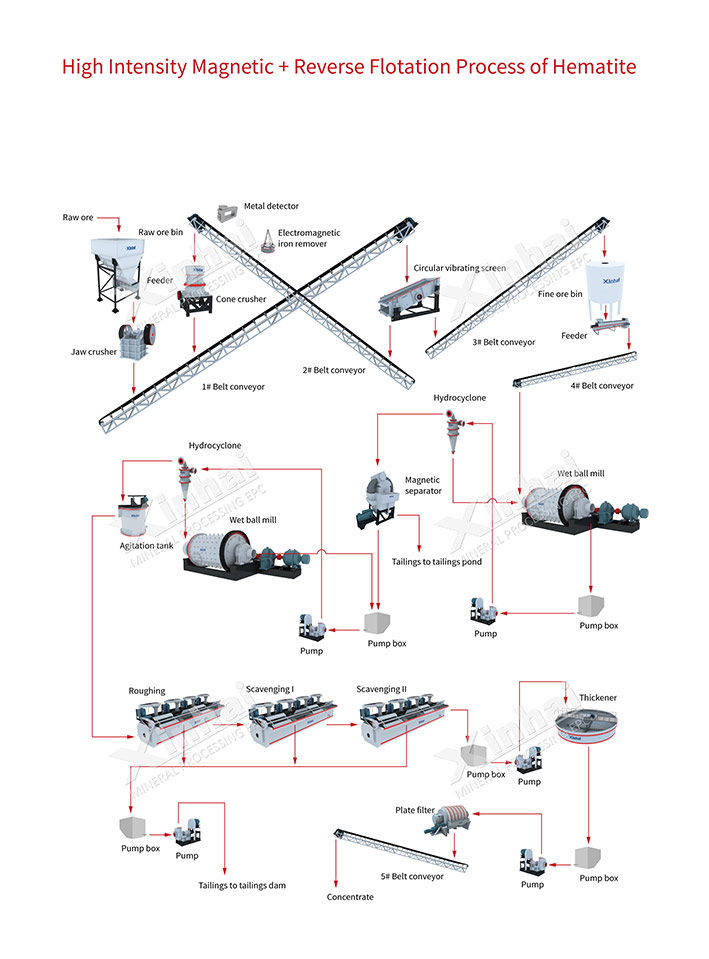

The hematite processing line adopting stage grinding and stage separation for high separation efficiency. The combination of strong magnetic separation and reverse flotation process ensures the concentrate grade and environmental protection.

In the first grinding and classification stage, ball mill and hydrocyclone consists the closed circuit. It guarantees the classification efficiency and classification particle size. At the same time, it separates part of regular concentrates at advance. Part of low-grade tailings are discarded by high-gradient magnetic separator. It can reduce the middling regrinding amount and metal loss, also avoiding overgrinding.

The magnetic separation can separate regular coarse concentrates and tailings in time, which fits the principle of early recovery and early discarding as possible. It also reduces the flotation workload and costs.

Strong magnetic separation can recover the fine particle iron ore. It has double effects of desliming and discarding tailings. It can provide good conditions for flotation operation.

Verse flotation has a simple reagent system, which can obviously reduce the flotation reagent into the slurry. It can reduce the adverse reactions of flotation.

Xinhai hematite beneficiation process can design a specific process according to the specific ore properties, and can also provide matching hematite to ensure that the production line meets the standard and reaches the output. At present, Xinhai has contracted nearly 100 sets of hematite production lines, of which the representative one is a hematite beneficiation equipment in the Philippines, with an annual output of 700,000 tons. , one refining, three cleanings, one three cleaning process and returning to the second stage of desliming operation. The comprehensive selection index is the concentrate grade of 69.7% and the recovery rate of 65.4%, far exceeding the customer's expectation.

流程图

流程图