Manganese mineral belongs to the weak magnetic minerals, which can be recovered by high-intensity magnetic separator. Xinhai applies the magnetic process to separate manganese mineral, including two stages, rough separate the high-intensity magnetic ore and concentrate the medium intensity magnetic ore, thus improving the manganese grade by 4% to 10%.

Xinhai adopts special high-intensity; Magnetic separator of manganese ore to remove impurities preliminary, then uses spiral classifier to classify rougher concentrate and rougher tailings directly discharge; At last, rougher tailings directly discharge into the tailings thickener.

The underflow of the classifier been delivered into the magnetic separator to concentration, and the overflow been dewatered at the thickener.

The concentration overflow discharged into the backwater system, the concentration underflow converged with the concentration becoming the concentrates.

In a manganese ore project, manganese minerals are mainly rhodochrosite and calcium rhodochrosite, followed by manganese calcite. Gangue minerals include quartz, chalcedony, carbon, clay, etc. Xinhai contracted the design of the mine's production process, and adopted the high-intensity magnetic roughing + medium-magnetic beneficiation process. The final grade of manganese concentrate was 38% and the recovery rate was 74%.

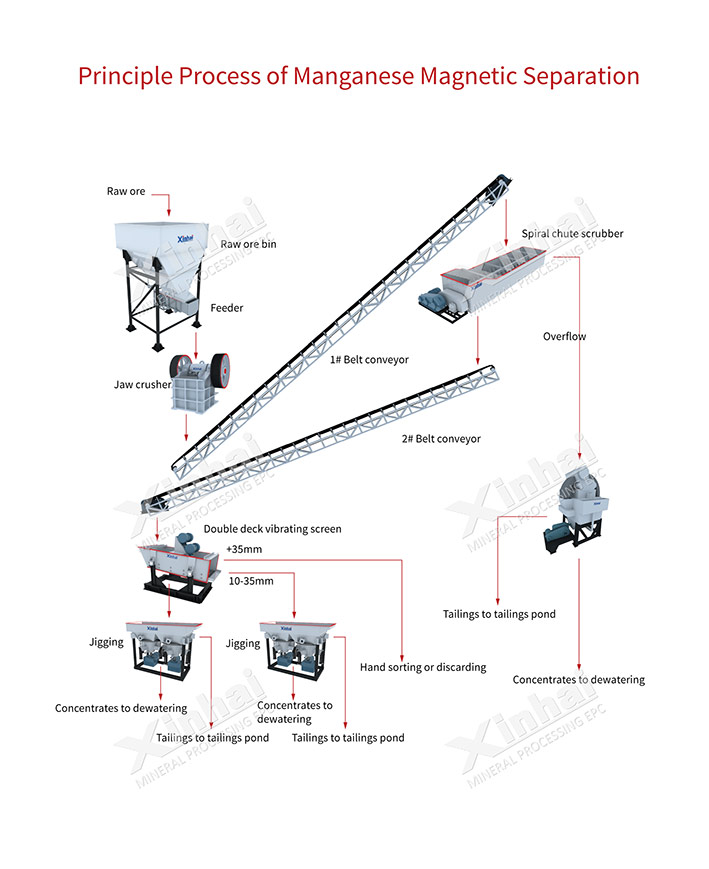

流程图

流程图